How do you go about determining what the condition of your embedded chainplates are in? There is not a magic window we can peer into. Two options are to X Ray the chainplates and Thermal Imaging. Since I have not seen the X Ray images in person I can not give much comment. From what I have seen posted online, I am skeptical if it can pick up on the hair line cracks that can form in the stainless. With Thermal Imaging we can not see the chain plate per-say, but see the trapped moisture. If salt water is trapped against the stainless then crevice corrosion can begin.

In the January edition of Boat US Seaworthy magazine there was an alert written to inform the boat owner of this type of inspection and the concern of embedded chainplates.

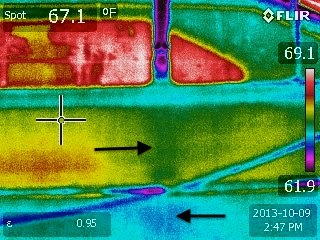

Below are images from an inspection of an Irwin.

I was able to follow the removal of the chainplates and inspect them after the were removed. Four out of the six suffered from crevice corrosion.

Trapped Moisture

Cracks:

and then cut in half:

You can see the small amount of good metal left in the chainplate.

I have also done an inspection on an Irwin that had trapped moisture and the owner reported that the chainplates, when removed did not have any corrosion. Most likely this boat had only fresh water trapped around the chainplates.

Image from the exterior indicating trapped moisture.

Link To the Boat US Alert:

https://www.boatus.com/seaworthy/magazine/2014/january/alert.asp